Ceramic

various sizes

Binary jugs

2018

2018 Commissioned by Binary Pottery (TW)

Concept

Digital craftsmanship

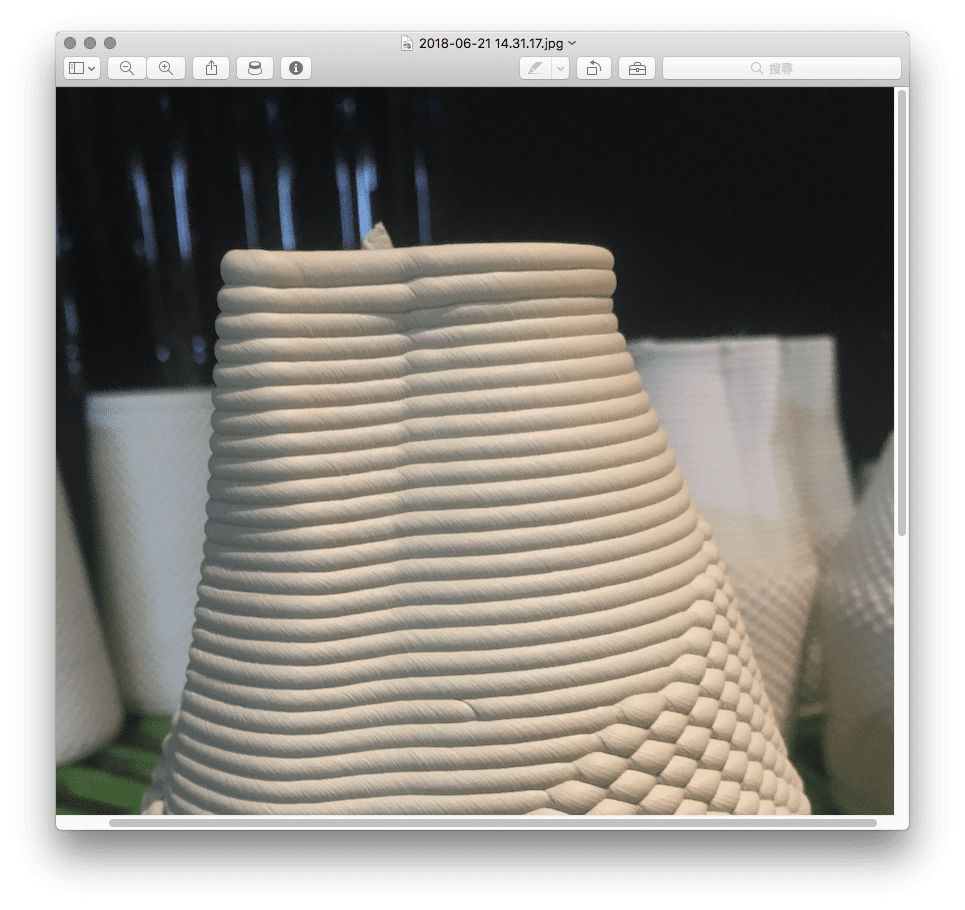

Commissioned by Binary Pottery which focuses on ceramic 3D printing, they have studied the making process for years, from the proportion of clay to the machine of extrusion. They also create their own route to lay down the coil interactively, not only showing the unique pattern on the surface but also strengthening the structure of the product.

Process

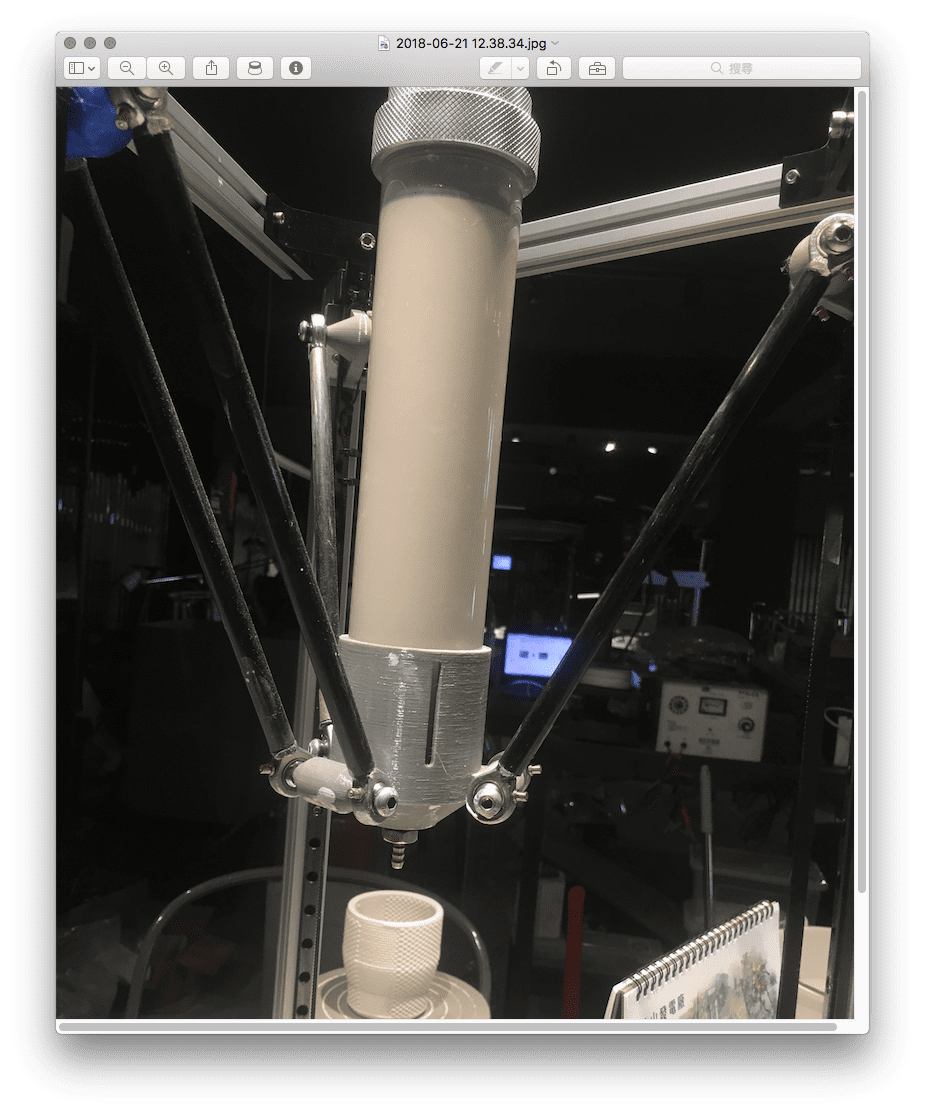

3D ceramic printing

However, the self-made machine has few restrictions, for instance, the limitation of width.

Due to that situation, the design will follow:

i. Width is smaller than 18cm and height is not taller than 25cm.

ii. Consider after baking will shrink around 15-20%.

iii. Preserve the dot pattern or improve it.

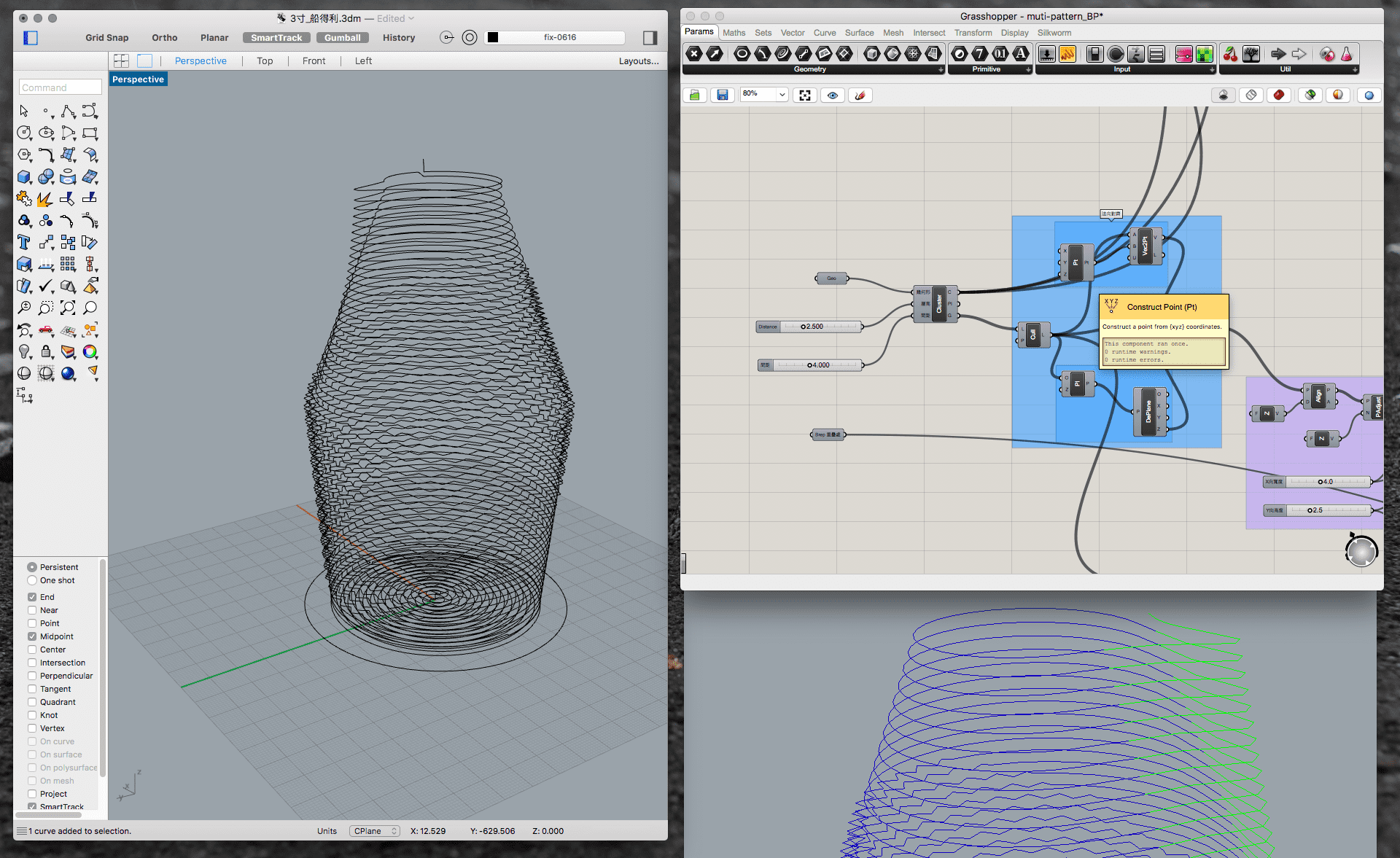

Also, they hope to develop tableware series based on these specs. This is where Erco Lai started to design and research.

The project has one advantage, which is making products and prototypes using the same machine. On the other hand,

he has to create G-codes via grasshopper. Thanks to the experience of digital fabrication, he can handle the procedure.

Nevertheless, Erco Lai believes and got inspired that this will be kind of factory and manufacturer of the future.

Further reading

Sake set

- More about process and result

Fieldstone

- The 3d-printed-stone table